|

| March 16, 2021 | Volume 17 Issue 11 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New Navy 3D-printed antenna designs reduce cost, weight, size

By Cassandra Eichner, U.S. Naval Research Laboratory

U.S. Naval Research Laboratory (NRL) experts are creating and testing 3D-printed antennas and arrays to advance radar technology and enable new applications for the U.S. Navy.

The lightweight and rapid production of 3D-printed parts makes it an attractive alternative to traditional manufacturing that often requires expensive materials and specialized equipment.

"3D printing is a way to produce rapid prototypes and get through multiple design iterations very quickly, with minimal cost," said NRL electrical engineer Anna Stumme. "The light weight of the printed parts also allows us to take technology to new applications, where the heavy weight of solid metal parts used to restrict us."

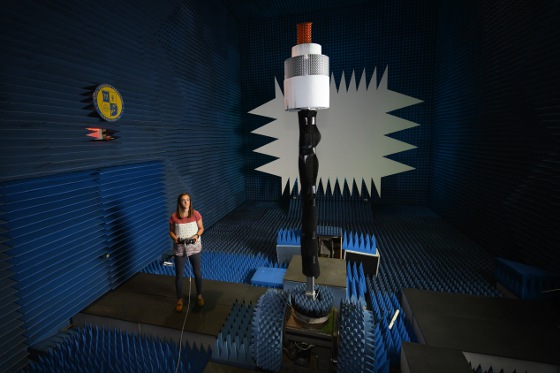

Anna Stumme, U.S. Naval Research Lab electrical engineer, makes adjustments to an array inside the anechoic chamber at the lab in Washington, D.C. Stumme creates and tests prototype parts developed using traditional and 3D-printed methods. [Photo by Jonathan Steffen]

Radar systems perform critical functions for the Navy and remain an important part of maritime navigation and national defense. Parts for antennas and arrays, which are multiple connected antennas working together as one, may unexpectedly break or wear out, requiring replacement. Traditionally, parts are ordered or intricately machined out of metal, sometimes taking weeks to produce. 3D-printed radar parts, such as a cylindrical array that provides 360-degree visibility, can be produced within hours versus several days using traditional methods due to the reduced machining and assembly time.

In addition to the production benefits, the relatively low cost of 3D-printing materials enables researchers to test multiple versions of parts at minimal overhead. The perfected prototypes can then be machined using traditional methods. Once a prototype is successfully produced, whether 3D printed or traditionally manufactured, it must undergo rigorous testing before it is used operationally. That's the "super power" of the technology, said Stumme -- they can quickly perform a variety of tests on new designs using 3D-printed parts.

"We are not trying to say we need to 3D print everything and put it on a ship, because that is not realistic," Stumme said. "We don't necessarily know how it would hold up in that environment. For us, it's a way to test more design iterations in a short amount of time."

In early 2019, Stumme submitted a paper comparing 3D-printed parts against traditionally manufactured parts at the Antenna Applications Symposium. She won the student paper contest for her research.

New applications

Stumme and her colleagues are investigating how weight- and size-constrained applications, such as unmanned aerial vehicles or small ships, can benefit from 3D-printed parts. Many of the 3D prototypes are printed using lightweight nylon in NRL's Laboratory for Autonomous Systems Research facility. Once the part is printed, it undergoes a process called electroplating.

During the electroplating process, a thin coat of metal is applied to the printed part. Electroplating provides a conductive surface for the device to radiate as intended; something that isn't feasible with plastic alone. The result is a lightweight prototype that can then be evaluated for a variety of attributes such as surface roughness -- a major factor in the functionality for antenna elements.

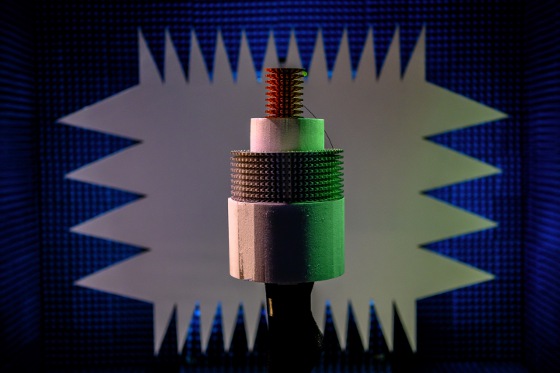

Two arrays await testing in the compact range at the U.S. NRL. The two white parts are Styrofoam supports -- between the Styrofoam is an array built using traditional machining methods (all metal cylindrical array). On top is a 3D-printed sector array. A setup like this can help compare the performance of traditionally manufactured parts against 3D-printed parts. [Photo by Jonathan Steffen]

Stumme collaborates with NRL materials scientists from across NRL to perform critical surface roughness characterization. Surface roughness characterization provides an assessment of the coating on an antenna, and the impact roughness has on its performance.

"Surface roughness is important for wave guides and antennas because it can cause scattering losses and result in a less efficient antenna," said Nick Charipar, head of the Applied Materials and Systems Section. "Antennas radiate and receive waves. So if a wave runs along a rough surface, it is distorted and the energy may not go where you want it to go."

Charipar and his team, part of NRL's Material Science & Technology Division, prototype 3D-printed parts for the NRL's Radar Division. Once the part is created, researchers investigate how the material features impact functionality of the radar. Each 3D printer has unique characteristics that may alter product performance. If researchers can figure out the optimal parameters for specific 3D-printed parts, Stumme and her colleagues agree ships could become self-reliant for those critical parts anywhere in the world.

Next steps

Despite current COVID-19 restrictions, research at NRL continues to thrive from a distance. Later this year, Stumme and her colleagues plan to demonstrate new prototype cylindrical array apertures for an X-band surveillance radar demonstration in a laboratory setting. The X-band surveillance radar is designed to search the area surrounding a particular platform, such as a ship. They are exploring integrating cylindrical arrays into the masts of smaller vessels using microwave photonics and optical fibers.

"Cylindrical arrays are advantageous because they provide full 360-degree visibility," said Mark Dorsey, head of the Antenna Section in the Radar Analysis Branch of the Radar Division and project principal investigator. "Optical fibers are valuable because they can allow for long separations between the antenna itself and where the processing is conducted."

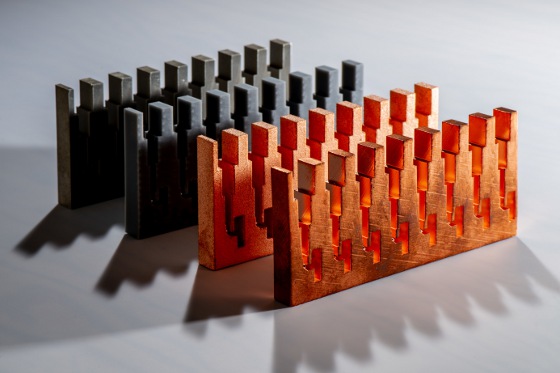

Manufactured column element parts of cylindrical arrays used for testing the viability of additive manufacturing to make cylindrical arrays at the U.S. NRL. From left to right: metal 3D print, stereo lithography (SLA) print, selective laser sintering (SLS) Nylon print with electroplating, and SLA print with electroplating. (Photo by Jonathan Steffen)

Using optical fibers reduces the number of components required on a Navy ship's mast, further reducing heat and weight constraints. The demonstration will include testing traditionally manufactured and 3D-printed versions of the array to compare performance. Stumme designed both versions.

In 2021, the team is scheduled to perform field testing on the prototype. The demonstration will be in the final year of their four-year effort to make the array more practical to use on smaller platforms, and show how to use arrays easily with optical fibers. Funding for the research is provided by NRL base funding.

Published March 2021

Rate this article

View our terms of use and privacy policy